Properties of Elastollan®

- Outstanding elasticity

- Good tear and abrasion resistance

- High Rebound

- Adjustable gas permeability

- Suitable for food contact applications

Automotive

Outstanding elasticity means that Elastollan® is particularly suitable for producing mono- and multi-filaments, as well for coating polyester and glass fibers. It can also be worked into nonwoven fabrics using the melt blown as well as spun bond techniques.

Polyester and glass fibers are processed into products including UV-resistant, highly flexible fabrics for shadingsystems and covering chairs. When it comes to decorative fibers, brushes and shoe uppers, Elastollan®- based materials are distinguished by their good tear and abrasion resistance and pleasant surface feel.

Nonwovens are used in filter, seal and hygiene applications. For these applications, particular importance is placed on product benefits such as elasticity of up to 500%, high rebound and adjustable gas permeability. Good weldability in high-frequency and ultrasound processes, or suitability for food contact applications can also be a reason for choosing Elastollan®.

We offer our customers a comprehensive range of services with leading technologies and products. Find the service that matches your needs!

Tailor-made for individual needs: We support our customers in developing application-oriented solutions.

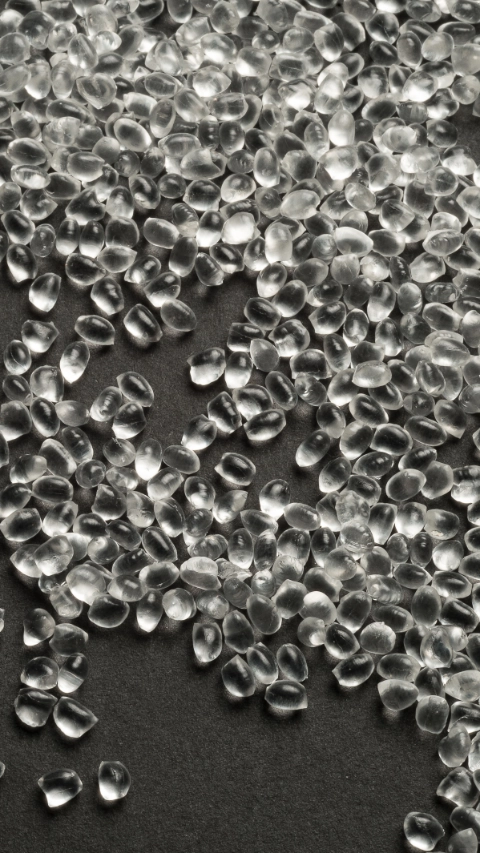

The following methods can be used for the processing of Elastollan®.