Key advantages of Ultradur®

- High rigidity and strength

- Very good dimensional stability under heat

- Low water absorption

- Good resistance to many chemicals

- Exceptional resistance to weathering

- Excellent heat aging behavior

Performance Polymers

Polybutylene Terephthalate (PBT)

Ultradur® is BASF’s brand name for its line of partially crystalline, thermoplastic, saturated polyesters derived from polybutylene terephthalate (PBT). They are employed as materials for high-quality technical components in many industry sectors.

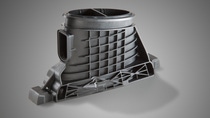

Ultradur® shows its strengths wherever high-quality and above all heavy-duty parts are required – for example in the automotive industry, in the electrics and electronic sectors. The range of applications which benefit from these properties of Ultradur® in both industry and everyday life is vast. A feature that is particularly important is the low water absorption and thus the fact that the mechanical and electrical properties are largely independent of the moisture content or the climatic surrounding conditions. Particularly for components that are safety-relevant and have to work reliably for the entire lifetime of a component, Ultradur® is indispensable.

Energy efficiency is an increasingly important aspect to consider, both from an economic and ecological perspective. The cycle time of the injection molding process plays a major role for the highlighted properties. To this end, BASF has developed a new variant of Ultramid® and Ultradur®, known as High Productivity Plus, which leads to significant reductions in cycle time and process energy consumption. First tests show a potential reduction of the cycle time around 30 %.

Ultramid® and Ultradur® HPP are high-performance thermoplastic resins that show outstanding flowability, faster crystallization and ability to be processed at lower melt temperatures making it an ideal choice for manufacturers and product designers who demand the very best in terms of efficiency and performance.

Ultramid® and Ultradur®’s ability to be processed at lower melt temperatures make it a more sustainable choice. Additionally, this resin requires lower injection pressure, which reduces wear and tear on equipment and extends the lifespan of molds and other components.

The most important applications of Ultradur® are automotive engineering, electrical engineering, electronics and telecommunications as well as precision engineering and general mechanical engineering. For these applications, a variety of Ultradur® types is available.

The Ultradur® grades are polyalkylene terephthalate molding compounds based on polybutylene terephthalate. Ultradur® is produced by polycondensation of terephthalic acid or dimethyl terephthalate with 1,4-butanediol using special catalysts. Terephthalic acid, dimethyl terephthalate and 1,4-butanediol are obtained from petrochemical feedstocks, such as xylene and acetylene.

Ultradur® can be processed by all methods known for thermoplastics. The main methods, however, are injection molding and extrusion. Complex moldings are economically manufactured in large numbers from Ultradur® by injection molding. The extrusion process is used to produce film, semi-finished products, pipes, profiled parts, sheet and monofilaments. Semi-finished products are for the most part machined further by means of cutting tools to form finished moldings.

The applications are as manifold as its product properties: Explore the various application possibilities of Ultradur®!

We offer our customers a comprehensive range of services with leading technologies and products. Find the service that matches your needs!

Self-service solutions: