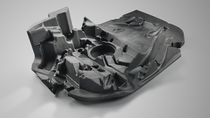

With the change from combustion engines to eMobility or fuel cells, the conventional engine cover may lose on significance in the (near) future, but acoustical challenges remain. Due to electrification, NVH concepts may need to be adjusted or repositioned and other frequencies must be considered.

Using either Elastofoam® or Elastoflex® systems from BASF always provides a solution for your NVH request. The benefit of our systems is that they are not restricted to specific application areas, and can be used as an acoustic solution regardless of the powertrain.

BASF’ Elastofoam® and Elastoflex® systems have established themselves in today’s automotive industry as a good NVH solution and will also remain in the future.