Automotive

Cellasto® seals for greater protection and durability

Standing up to wear and tear can be grueling, but in your machinery, it shouldn’t have to be. Cellasto® provides durable and high-performance protection, especially in assemblies with relative movements such as rotative bearings.

That’s why trailblazers worldwide are applying it in the design of their dynamic seals for a wide array of applications, from mining and construction to printing and medical equipment.

What are dynamic seals?

Dynamic seals protect valuable, high precision bearings from water, grit, and other harmful materials, while also keeping vital lubricants inside. Moreover, Cellasto® can store grease or oil, enabling long-lasting lubrication of sensitive metal surfaces.

With both high compressibility up to 35% static pre-load and low lateral expansion under compression, Cellasto® provides longer-lasting protection by maintaining the contact force needed to reduce wear. Not only that, but this microcellular polyurethane foam stands up to friction better than conventional elastomers without adding resistance, so the material itself lasts longer.

In addition, Cellasto® provides dependable, consistent protection at both high and low temperature extremes of operation and environments. Therefore, designing your machinery with Cellasto® will provide unparalleled durability and boost your product’s competitive edge.

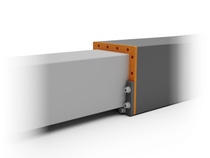

See Cellasto® seals in action

Ways to use Cellasto® seals

To maximize bearing protection, your team can design dynamic seals with Cellasto® for a wide range of demanding applications. Here are a few examples of how Cellasto® has become the insider’s secret for greater durability and protection:

A flexible material that can meet a variety of specifications

Take advantage of the amazing versatility of Cellasto® by co-creating custom solutions that meet your product’s specifications.

With BASF, experts will help you design, test and continuously update your customized components so you can continue to deliver the durable, high-performance products your customers need and deserve.

Additional resources

Explore our knowledgebase of brochures, videos and other resources to expand your engineering insight and spark your creativity.